Move comes as Norfolk Southern is returning two idled humps to service

OMAHA, Neb. — Are hump yards making an unlikely comeback?

Probably not, although three mothballed humps are once again using gravity to classify freight cars.

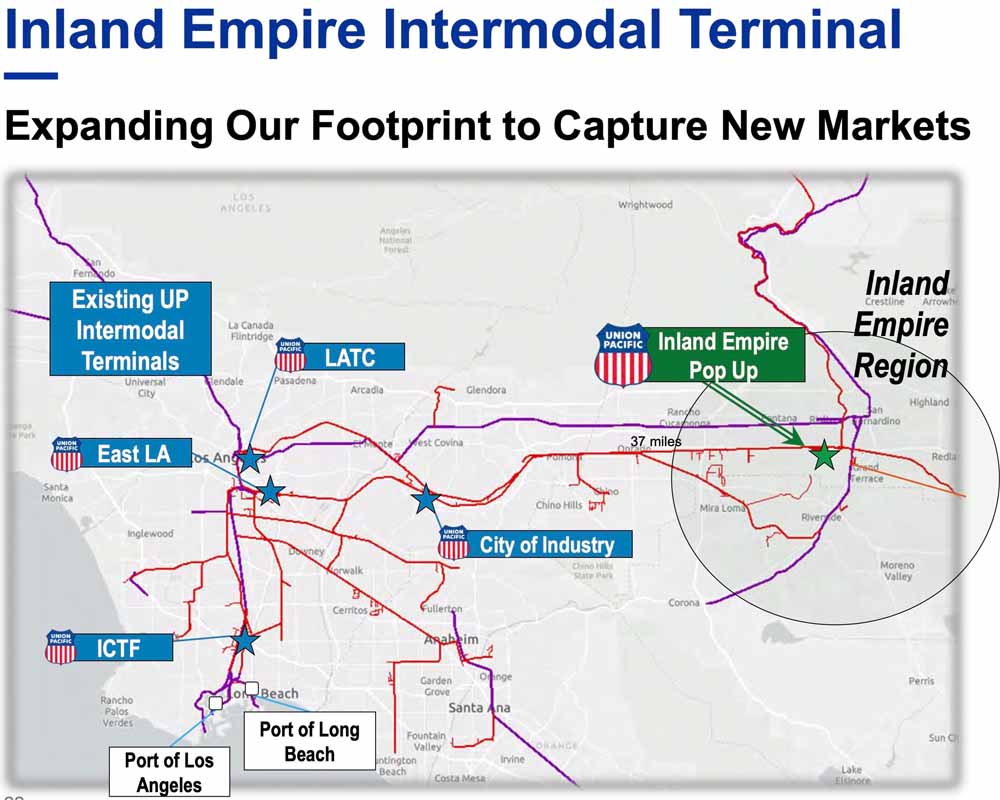

Union Pacific has reactivated the hump at Davidson Yard in Fort Worth, Texas, to ease the burden on the classification yard at West Colton, Calif., where UP is expanding the small “pop-up” intermodal terminal it opened in the summer of 2021.

“We recently began operating the Fort Worth hump as part of a strategic plan to reduce manifest switching operations at West Colton,” spokeswoman Robynn Tysver says. “The move facilitates expansion of our intermodal ramp serving the Inland Empire intermodal market. Humping operations will continue at West Colton but at a reduced level as the next phase of intermodal construction begins.”

Norfolk Southern announced last week that it is running cars over the hump at Brosnan Yard in Macon, Ga., and will soon resume hump operations at Moorman Yard in Bellevue, Ohio, after maintenance work is completed.

What Davidson, Brosnan, and Moorman yards have in common is that they were idled as part of each railroad’s shift to an operating model based on the principles of Precision Scheduled Railroading. CSX Transportation, NS, and UP have idled or completely shut down a combined 19 hump yards since March 2017.

Some of the shutdowns were relatively short-lived, such as at Radnor Yard in Nashville on CSX and DeButts Yard in Chattanooga on NS.

UP idled the hump at Davidson Yard in January 2020. It was the fifth hump shut down since UP adopted PSR in late 2018. UP also canceled the completion of its proposed Brazos Yard that was being built near Hearne, Texas.

Yet the hump yard trend at UP has not been all downhill: The railroad has improved and expanded Englewood Yard in Houston. The hump received a new master retarder in December 2020. UP subsequently added a new hump control system at Englewood, along with new signals, new switches and ties, and extended bowl tracks so the railroad could assemble longer trains. UP also replaced three bridges in the yard.

UP and NS declined to say whether the reopening of the humps would be temporary measures or more long-term operational changes.

The conversion of hump yards to flat-switching facilities — or shutting them down outright — has been among the most visible moves of the late E. Hunter Harrison’s PSR operating model.

“Is this a retreat from PSR? Absolutely not,” says independent analyst Anthony B. Hatch.

The idling of humps was an outcome of PSR and was not among its goals, Hatch says.

Operational changes — such as pre-blocking cars at origin, block-swapping cars en route, and pushing switching to smaller yards — starved humps of the volume they needed to remain open.

Humps remain the most efficient way to classify high volumes of traffic, but before PSR many railroads ran cars out of route simply to reach a hump yard or ran cars through more humps than necessary on their journey across the railroad. That inflated hump yard volumes while slowing service.

It takes cars 24 hours or more to make their way through a hump, versus 6 to 8 hours in a block swap, railroad operating officials say.

Since adopting PSR, UP’s switching volume is down by nearly a third, CEO Lance Fritz has said, because the railroad touches cars fewer times en route.

When UP converted Davidson Yard to a flat-switching facility, about half of its volume was parceled out among nine smaller terminals in the Texoma Service Unit in Texas and Oklahoma.

During its earnings call last week, NS officials said they once again needed the switching capacity that Macon and Bellevue provide.

“We reactivated these humps to give ourselves some additional capacity that we need in two areas served by Macon and Bellevue. The way switching demand has evolved since 2020, there’s enough critical mass to justify returning them to service as hump yards,” Chief Operating Officer Cindy Sanborn said. The move also was made to concentrate traffic at Macon and Bellevue in order to free up yard crews elsewhere for use in local service amid ongoing crew shortages.

“Flat switching is slower — and harder — and when combined with inexperienced crews is a fluidity problem,” Hatch says, pointing to a KBX Rail presentation from the North American Rail Shippers conference this year.