HS2, Britain’s high-speed rail project, is buried in statistics. However, there is one statistic that burrows its way out from all the others. 646 freight trains have delivered one million tonnes of construction materials to the HS2 construction site at Quainton, around fifty miles (80km) north of London Euston – or 45 miles north of the terminal at Old Oak Common, if you remain sceptical about the eventual buffer stops on the line between Birmingham and the UK capital.

The construction railhead near Aylesbury in Buckinghamshire has received, on average, a train every eighteen hours over the past 16 months. Those 646 trains have taken the equivalent of more than 101,000 heavy goods vehicle journeys off local roads. It is expected that HS2 trains, when they start running, will be somewhat more frequent. Nevertheless, acknowledging that statistic is as close as Buckinghamshire has come to welcoming HS2.

Rail freight the only viable way of moving that volume

The company building Britain’s new high-speed railway has evoked the spirit of Victorian railway pioneers. When HS2 Limited chose Quainton as its construction base in Buckinghamshire, they were not the first to exploit its position. The countryside location has figured in the plans of railway barons, eager to expand the London commuter belt and also establish a nineteenth-century international railway all the way from the north of England to Paris. It is also host to an important railway heritage site which straddles the existing freight line.

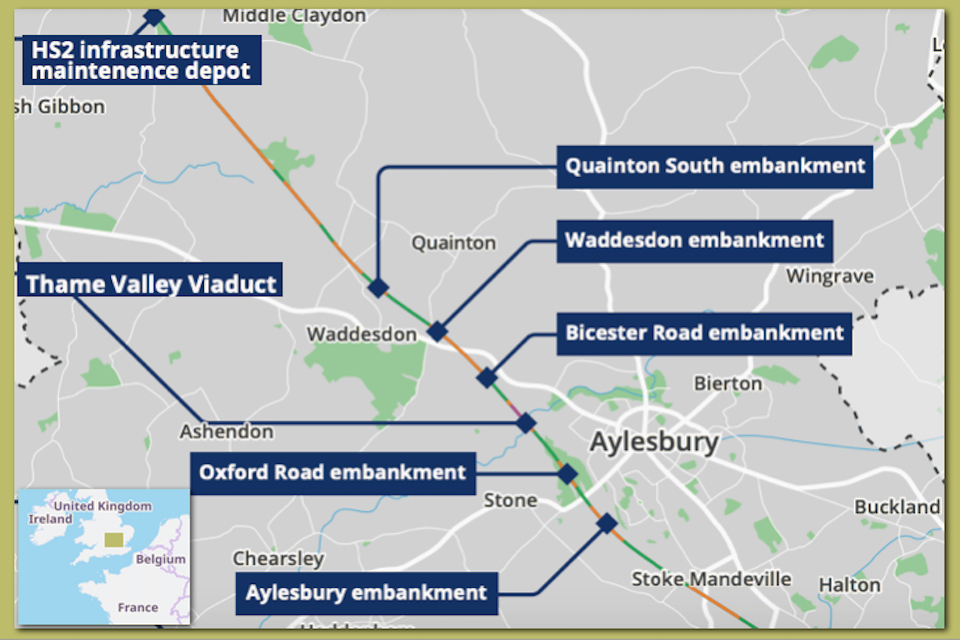

Quainton is now at the centre of construction operations to build the high-speed railway between London and Birmingham. Visitors to that heritage centre have a first-class view of traffic to and from HS2 operations. If anyone has been counting (and HS2 most certainly has), they would have recorded those 646 trains, delivering a combined load of a million tonnes of construction materials. Rail freight seems the only viable way of moving that volume of bulk commodities around the country.

Supply chain benefits include rail freight

“We know that the local community are concerned about construction traffic”, said Ben Sebastian-Green, HS2 Ltd Senior Project Manager. “It’s great to be able to get so much material into site by rail. Not only does it take traffic off local roads, but it also saves carbon and helps to streamline our logistics. Alongside delivering zero carbon journeys for passengers, we’re also cutting the amount of carbon in construction.”

The bulk of the material delivered is construction aggregates. The raw materials are sourced from several sites around Britain, giving some credence to HS2’s claims that the national supply chain benefits directly from the project. Once on site, most of the material is stockpiled before being moved up or down the new high-speed line route on a series of dedicated haul roads to keep it away from local road users.

Hoped for capacity enhancements compromised by government action

The future benefits to rail freight should be evident in the capacity released on the British railway network. However, the UK Government has cancelled almost all of the projects beyond the London—Birmingham shuttle. Questions have been raised about the effects that will have on the overall network timetable. Whether or not the hoped-for capacity is released, particularly on the very busy West Coast Main Line, remains to be seen.

There is no doubt about the present-day benefits of the HS2 construction project. The British rail freight industry is playing a huge part in the building of HS2. That is most apparent at Quainton. Situated on an existing freight line north of Aylesbury, the railhead is expected to welcome an extra 1,400 freight trains over the next two years, taking the total amount of material delivered to around three million tonnes.

Turning freight railhead opportunities into a reality

HS2 is, in effect, a linear construction site more than one hundred miles (160km) in length. Movement along the line is no different from any other railway project. It is simply on a scale larger than almost anything seen in the UK since the construction of the HS1 Channel Tunnel Rail Link, between London and Folkestone. The one million tonnes delivered to Quainton is in addition to deliveries of another one million tonnes to previously established local railheads.

“Moving material by rail was always an essential part of our strategy to help deliver this project efficiently”, said Paul Bedford, the Head of Logistics and Security for the construction joint venture partnership, EKFB. “The original strategy was to utilise existing railheads across neighbouring counties and move the material the last few miles to the site by road. We quickly realised that there was an opportunity to establish our own railheads within the project area, and through the hard work of all involved, we turned this opportunity into a reality.”